How does a straight line cable roller work with cabling equipment?

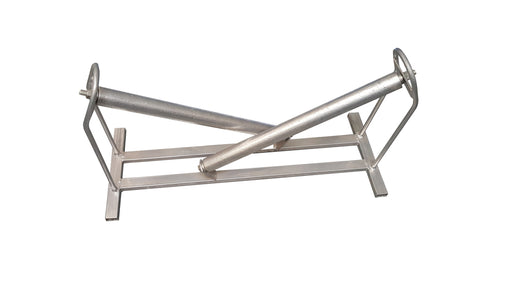

A straight line cable roller is designed to guide cable smoothly and efficiently along a set path during installation, reducing friction and preventing cable damage. When paired with other cabling equipment, it becomes part of an essential handling system.

For example, using Hydraulic Jacks allows you to safely lift and support heavy cable drums, enabling controlled unspooling. Once the drum is elevated, the cable feeds directly into the straight line rollers, keeping it aligned and supported throughout the pull.

Similarly, Cable Dispensers work in conjunction with straight line rollers to control payout speed and prevent tangling. The dispenser releases the cable at a steady rate, while the roller system maintains the correct path and minimises drag. This combination is particularly valuable in applications such as power distribution, telecoms, and construction, where large volumes of cable must be handled quickly and safely.

Straight line rollers work seamlessly with other cable management tools. Combining different cable handling equipment creates a complete cable handling setup, improving efficiency and safety on-site.

What’s the difference between a straight line roller and a manhole entry roller?

While both a straight line roller and a manhole entry roller are essential tools in cable installation, they serve very different purposes. Straight Line Rollers are designed to guide and support cables along flat, straight runs. These rollers minimise friction and prevent cable damage by lifting the cable clear of the ground during the pull, making them ideal for long-distance or open-surface installations.

In contrast, Manhole Entry Rollers are built to assist when feeding cable into or out of a manhole or underground chamber. These rollers sit at the edge of the manhole, guiding the cable smoothly over the lip and reducing wear on both the cable and the chamber edge.

The key difference lies in their application: straight line rollers are for maintaining alignment and protection across straight cable runs, while manhole entry rollers manage directional changes and protect the cable when entering confined spaces. In many cable installation projects, both types of rollers are used together to create a seamless, safe, and efficient cabling route.

How should I best use a straight line cable roller for safe and efficient cable installation?

When using a straight line cable roller, correct spacing and handling are key to preventing cable damage and ensuring a smooth pull. For cable drums weighing up to 10 tonnes, it’s recommended to place the rollers in the trench at intervals of 2 to 2.5 metres. If the drum is heavier than 10 tonnes, shorten the spacing to 1.5 to 2 metres. This keeps the cable supported along its entire length, reducing strain and friction during installation.

Avoid leaving lead-sheathed cables resting on the rollers overnight. Over time, the cable can sag between the rollers, which may lead to physical damage or deformation of the sheath. If work stops, always remove the cable from the rollers or ensure it’s properly supported.

Using the correct straight line cable roller setup ensures a controlled, damage-free installation process. For other quality roller options, you can explore our Manhole Cable Rollers, Angle Corner Rollers and Suspension Rollers for more specialist applications